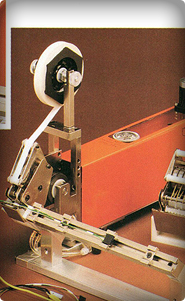

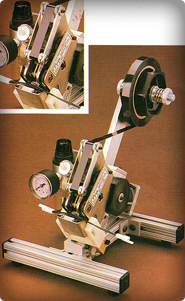

Semi- Automatic Wire Spot Taping System

(Click on thumbnail to enlarge)

| Spot Taping System Video |

Handheld Spot Taping System Video |

The Gettig Spot Taping System, now produced by our team at Spring Mills Manufacturing, Inc., has a sterling reputation as a reliable, low-maintenance machine. Bundles between 0.125" and 1.5" can be taped at rates up to 600 applications per hour. Paper tape with a rubber adhesive backing can be used for temporary applications, such as transfer between assembly areas, to prevent cords and wires from becoming tangled. For permanent applications such as binding wires in vehicles, polyester tape with either acrylic or silicone adhesive is used. Clear, black, and white tape colors are available and specialized colors or printing is available on request.

Our taping system has been proven to withstand brake fluid, antifreeze, and motor oil in lab testing and is ideal for long term bundling applications. The cost of each application is in the range of a few thousandths of a cent, making the Return on Investment (ROI) on the Gettig Spot Taper almost immediate when combining material and labor savings. When we purchased the right to manufacture the Gettig Spot Taper, we maintained Gettig's facilities and the vast majority of the company's long-term personnel. Customers should expect a seamless transition with no degradation to the quality of the product and a renewed dedication to customer service. For more information about the Gettig Spot Taping System, see the table below, or contact us directly.

Semi- Automatic Wire Spot Taping System Capabilities

- Product Name

- Semi-Automatic Spot Taping System

- Function

- Wire Bundling

Taping

- Features

-

- Optional Integration into In-Line Systems

Customizable - Low-Maintenance

Reliable

- Optional Integration into In-Line Systems

- Applications

-

- Wiring

Hoses - Cables

Tubing

- Wiring

- Bundle Diameter

- 0.125" to 1.5"

- Tape Material

- Paper

Vinyl (UPVC)

Polyester

- Tape Color

- Polyester Black

White Clear

Paper and Vinyl - any color is available

- Adhesive

- Silicone & Acrylic available in Polyester

Rubber is available for Paper and Vinyl

- Production Rate

- Up to 600 Applications per Hour

- Successful Exposure Testing Conditions

-

- Antifreeze

Brake Fluid

Motor Oil - Salt Water

Transmission Fluid

Windshield Washer Fluid

- Antifreeze

- Tested Temperature Range

- -40°C to 150°C is Polyester

Paper and Vinyl are -4°F to 158°F

- Lead Time

- Quoted on a Job by Job Basis

Expedited Service Available

Additional Information

- Industry Focus

- Automotive

Electronic

Hydraulic

- Industry Standards

- UL 510 Flame Test is for Polyester tapes not Paper or Vinyl

Print This Page

Print This Page Email This Page

Email This Page